|

|

| 35 OVER YEARS INDUSTRY EXPERIENCE | |

Click here to download the video: VIDEO

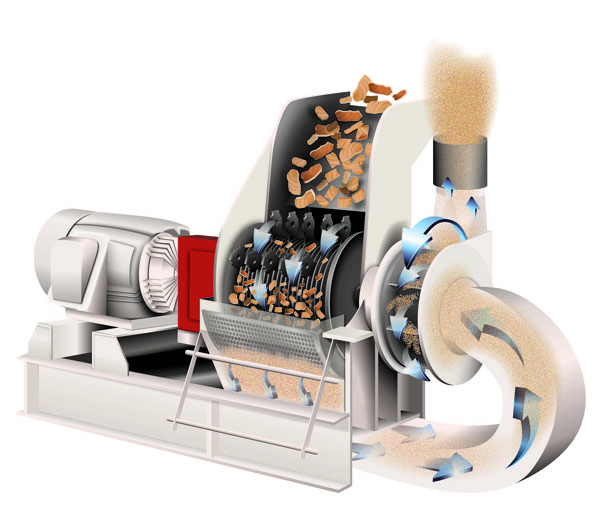

A BREAKTHROUGH CONCEPT

The practical, modern and environmentally safe way to get rid of scrap wooden

pallets. The completely integrated system feeds pallets automatically, removes

all nails, screws and staples, and produces a finely ground mulch - in a single

pass. No secondary operations of any kind are needed. And it meets all EPA,

DEC and other government requirements for the safe disposal of solid waste.

HANDLES FULL SIZE PALLETS

Standard 48" wide pallets are placed on the vibrating steel bed, nails

and all, and fed into the mouth of the unit where four rows of heat-treated

steel hammers "hogerizes" them. The finely-ground particles, along

with the nails and other tramp iron, are sucked into an automatic rotary drum

magnetic hump tunnel by a powerful 40-50 HP material handling fan.

COMPLETELY REMOVES NAILS

In a specially-designed automatic rotary drum magnetic hump tunnel, the mixture

suddenly changes direction, momentarily reducing its velocity. Permanent plate

magnets "reach out" and pull the nails and other metal objects from

the flow. The ground wood continues through the fan blades and into a trailer

to be hauled away, into storage, or for further processing.

New Pallet Scrap Grinder Models

We now offers the Model 4235 and Model 3035 Pallet Scrap Grinders, smaller units

for processing wooden pallet scrap and other wood scrap materials into a uniform,

first quality grind. These models are ideal for lumber mills, furniture plants,

recycling facilities and other operations for processing trim scrap, cardboard,

boxes, paper products and more.

Specifications

Model 5635

Out-Put: Animal Bedding, Fuel, Mulch

Model 4235 Pallet

Out-Put: Animal Bedding, Fuel, Mulch

Model 3035 Pallet

| COMPARISON | ||

|

|

|

|

|

|