|

|

| 35 OVER YEARS INDUSTRY EXPERIENCE | |

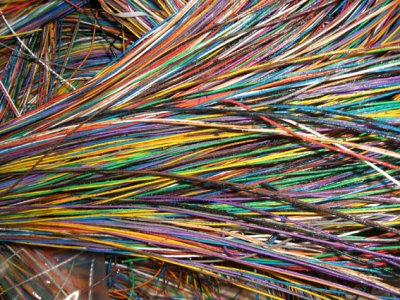

Recycle all sorts of cables & wires - including fiber optic wire, telephone wire, computer wires, e-waste wire, ultra fine wire.

This technology recycle, extract the precious metals and seperate the wires from the rubber/plastic wire casing.

This is an innovative and proven recycling machinery sold world-wide.

You will get concentrated copper, brass and steel fine powder of about 20-30 meshs.

You also get concentrated rubber in tiny pellet form which you can sell directly to rubber and plastic recycling firms.

Click here: VIDEO 1 - VIDEO 2 - VIDEO 3

This is a 3 in 1 machinery without using water.

The advantage is it's a dry process, meaning you don't have to wet your materials which cause condensation to the copper, steel and brass.

Plants have been set up to recycle eletric cables by means of a new system that grinds and dry-separates copper or aluminium from plastic or rubber. They are fully sound proofed and equipped with a de-dusting system (There is no emission of dust in the environment).

All models have the following specifications:

- Low power requirement

- Small dimensions

- Easy to move, place and install

- Easy and rapid maintenance.

- Capacity ranging from 100 to 1,000 KG per hour.

- Fully sound proofed.

- Equipped with a de-dusting system (There is no emission of dust in the environment).

- 4 Models available for 100, 200, 400 & 1000 KG per hour respectively.

| Model | Length | Width | Height | Weight | Installed Power | Production |

| 315C | 1200 mm | 1350 mm | 1830 mm | 700 Kg | 7,5 kW | 80-100 kg/h |

| 415C | 2100 mm | 1390 mm | 1980 mm | 1190 Kg | 12 kW | 150-200 kg/h |

| 530C | 2560 mm | 1600 mm | 2420 mm | 1800 Kg | 22 kW | 300-400 kg/h |

| 950C | 4000 mm | 2070 mm | 2550 mm | 3000 Kg | 48 Kw - 400 V - 50 Hz | 900-1100 kg/h |